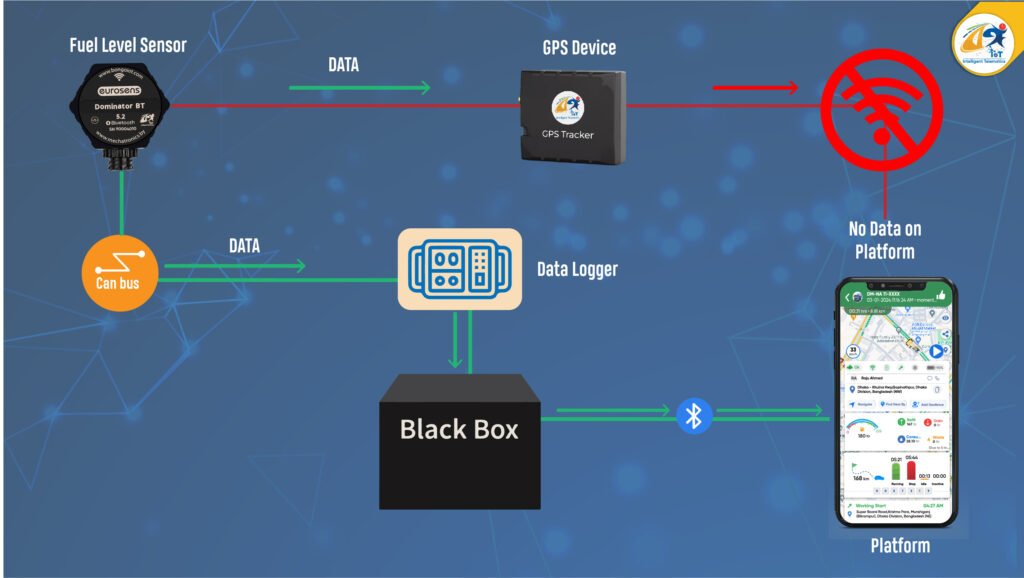

In telematics, receiving data from sensors via the internet is crucial, but limited connectivity issues can lead to data loss. Recently in Bangladesh, a nationwide internet shutdown lasting over 10 days highlighted the challenge of maintaining data continuity. During such disruptions, vehicle owners struggle to track fuel consumption without internet access. To address this issue, Bongo IoT has introduced the Blackbox feature, which stores data locally when internet connectivity is unavailable. In this blog, we will explore why the Blackbox is essential for fuel level sensors, especially during internet outages.

What is a Black Box in a Fuel Level Sensor?

In the context of fuel level sensors, a “black box” refers to an onboard data recording device that captures and stores various parameters related to fuel management. Much like the black boxes used in aviation, these devices are designed to record critical data that can be used for analysis, troubleshooting, and ensuring operational continuity.

Why is the Black Box Important?

The black box in fuel level sensors ensures reliable fuel management by recording data continuously, even without internet access. It provides uninterrupted data collection, maintains integrity with tamper-proof storage and backup power, and supports real-time adjustments and post-event analysis. It also aids in regulatory compliance, preventive maintenance, and informed decision-making. During disruptions like internet shutdowns, it ensures data resilience and recovery.

1. Continuous Data Recording

- Uninterrupted Monitoring: The black box ensures that fuel data is recorded continuously, regardless of internet connectivity. This is crucial for maintaining accurate records of fuel usage and levels.

- Data Completeness: By capturing all relevant data points, the black box provides a complete picture of fuel consumption patterns, which is essential for accurate analysis and informed decision-making.

2. Data Integrity and Security

- Tamper-Proof Storage: The black box stores data securely, protecting it from tampering. This ensures that the data remains accurate and reliable, which is vital for audits and compliance purposes.

- Backup Battery: Equipped with a backup battery, the black box continues to record and store data even during power outages or system failures, ensuring no data loss.

3. Operational Efficiency

- Post-Event Analysis: After internet connectivity is restored, the data stored in the black box can be analyzed to understand fuel consumption patterns during the outage. This helps in making necessary operational adjustments.

- Real-Time Adjustments: Even without internet access, the black box allows for real-time monitoring and management of fuel levels, maintaining operational efficiency.

4. Compliance and Reporting

- Regulatory Compliance: Accurate and continuous data recording helps organizations comply with fuel usage regulations by providing reliable data for reporting.

- Detailed Reporting: The black box enables precise and comprehensive reporting, which is essential for internal audits and regulatory compliance.

5. Preventive maintenance and issue detection

- Early Warning Systems: Continuous data recording helps identify patterns that may indicate potential issues such as leaks or unusual consumption rates. Early detection allows for preventive maintenance, reducing the risk of major failures.

- Maintenance Scheduling: Accurate data helps in planning and scheduling maintenance activities, ensuring vehicles and equipment remain in optimal condition.

6. Enhanced Decision Making

- Informed Decisions: Reliable and continuous data enables fleet managers and vehicle owners to make better-informed decisions regarding fuel management, route planning, and overall operational strategies.

- Cost Savings: Efficient fuel management based on accurate data leads to significant cost savings, optimizing fuel use and reducing waste.

7. Operational Resilience

- Minimizing Disruptions: In scenarios like internet shutdowns during protests or other disruptions, the black box ensures that critical fuel data is still recorded, minimizing operational impact.

- Data Recovery: Once normal operations resume, the stored data can be retrieved and integrated into central systems for comprehensive analysis.

How Does the Black Box Work?

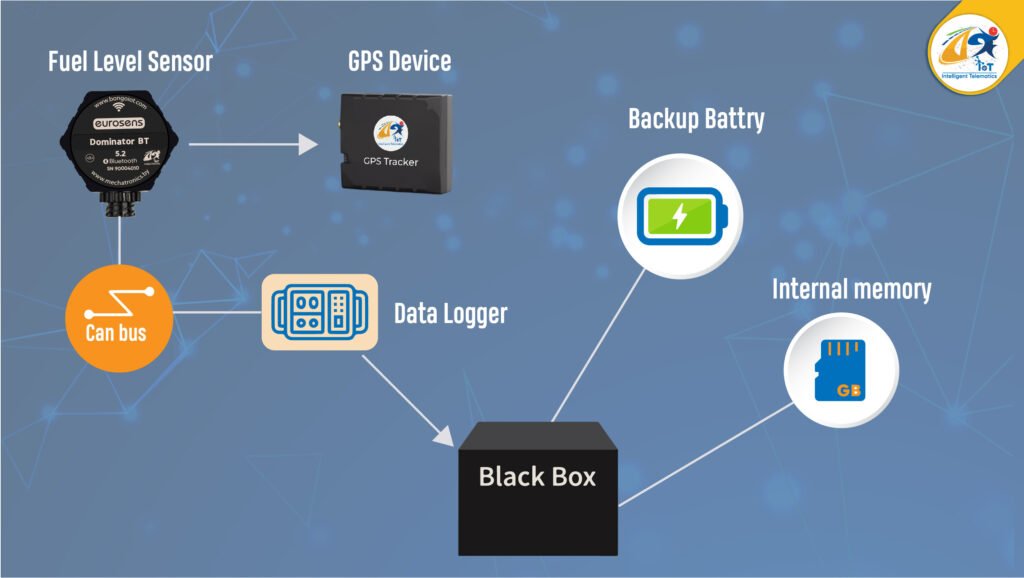

The black box in a fuel level sensor system includes several key components: the fuel level sensor measures fuel levels and sends real-time data to the black box, which also collects data from other sensors. The data logger time-stamps and records this data in flash storage, backed by a battery for power outages. Communication interfaces include wired options like RS232 and wireless options like GSM and Wi-Fi for data transmission.

Components and Functionality:

1. Fuel Level Sensor:

- Measurement: Measures the fuel level in the tank using technologies like float-type sensors, capacitive sensors, or ultrasonic sensors.

- Data Generation: Generates real-time data on fuel levels, which is transmitted to the black box.

2. Data Logger:

- Data Collection: Collects data from the fuel level sensor and potentially other sensors such as temperature and pressure sensors.

- Time Stamping: Each data point is time-stamped, ensuring accurate chronological records.

3. Memory Storage:

- Internal Memory: Stores the collected data in flash storage, which can hold several days to months of data depending on capacity.

- Backup Battery: Ensures continuous recording during power outages.

4. Communication Interface:

- Wired Interfaces: Includes RS232, RS485, and CAN bus for connecting the sensor to the data logger.

- Wireless Interfaces: Options like GSM, GPRS, 3G, 4G, Wi-Fi, or Bluetooth for remote data transmission when connectivity is available.

How Does It Ensure Data During Internet Loss?

The black box ensures uninterrupted data recording by storing data locally, which continues even when internet access is lost. It features tamper-proof memory for secure data retention and a backup battery to maintain recording during power outages. Data can be accessed locally via a direct connection and transmitted remotely to a central server or cloud-based system once connectivity is restored. Integration with fleet management software allows for comprehensive analysis and reporting.

Uninterrupted Data Recording

- Local Storage: The black box stores data locally, ensuring continuous recording even when internet access is unavailable. This local storage acts as a buffer, capturing all data until connectivity is restored.

Secure Data Retention

- Tamper-Proof Memory: Data is stored in a secure, tamper-proof memory, ensuring its integrity and reliability.

- Backup Power: The inclusion of a backup battery ensures that data recording continues uninterrupted during power outages or system failures.

Data retrieval and integration

- Local Access: Data can be accessed locally by connecting a device (e.g., laptop) directly to the black box.

- Remote Transmission: Once internet connectivity is restored, the stored data can be transmitted wirelessly to a central server or cloud-based system for analysis and integration.

- Software Integration: Data is often integrated with fleet management software, providing comprehensive insights and reports

Conclusion

The black box in a fuel level sensor is a vital component for ensuring reliable, continuous, and secure fuel data recording. Its importance is particularly highlighted during internet disruptions, as it provides uninterrupted monitoring and data storage. This enhances operational efficiency, ensures compliance with regulations, aids in preventive maintenance, and supports informed decision-making, ultimately leading to cost savings and improved operational resilience.

🌐Discover more

Visit at:

https://www.bongoiot.com/fuel-management

WhatsApp:

or,

Mail Us: